How 3D Printing Technology Works

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. Unlike traditional manufacturing methods that often involve cutting or molding, 3D printing builds objects layer by layer, allowing for complex shapes and customization.

Key Steps in 3D Printing

-

Designing the Model:

The process begins with creating a digital 3D model using Computer-Aided Design (CAD) software or by scanning an existing object. -

Preparing the File:

The model is converted into a format (usually STL or OBJ) that the printer can understand. Slicing software then divides the model into thin horizontal layers. -

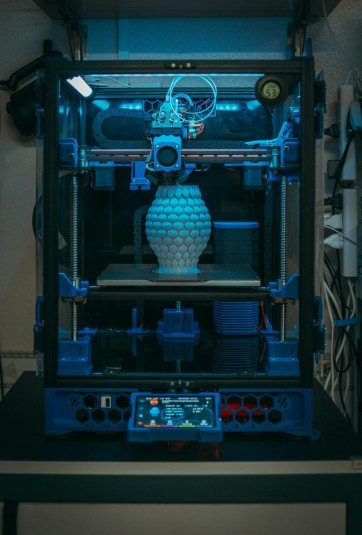

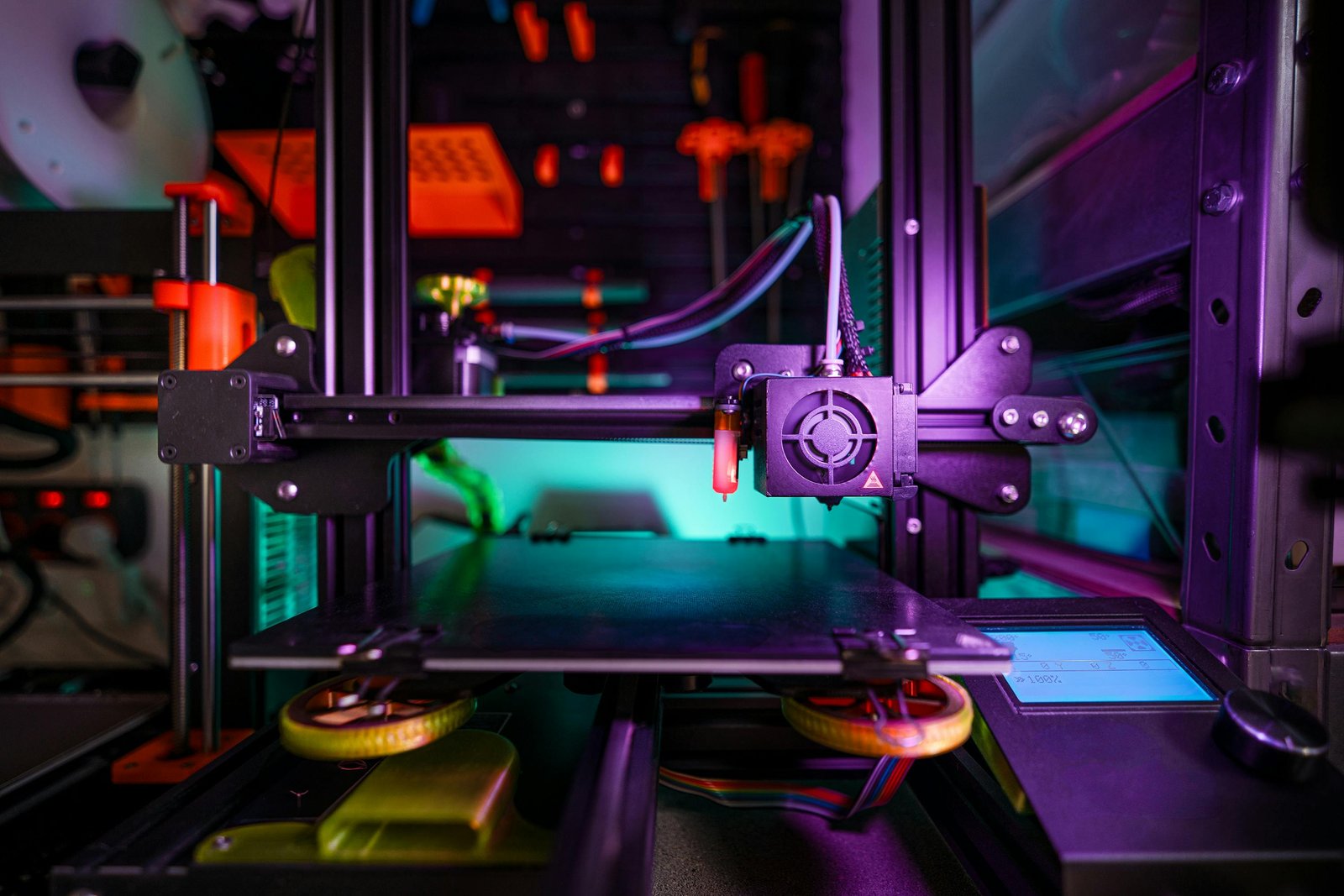

Printing:

The 3D printer reads the sliced file and deposits material layer by layer to build the object. Common materials include plastics, resins, and metals. -

Post-Processing:

After printing, the object may require cleaning, curing, or finishing touches to improve its strength and appearance.

Popular 3D Printing Technologies

- Fused Deposition Modeling (FDM): Melts and extrudes thermoplastic filament to form layers.

- Stereolithography (SLA): Uses a laser to cure liquid resin into solid layers.

- Selective Laser Sintering (SLS): Fuses powdered material using a laser.

Did you know?

3D printing is used in industries like healthcare, automotive, aerospace, and even fashion for rapid prototyping and manufacturing customized products.

3D printing is used in industries like healthcare, automotive, aerospace, and even fashion for rapid prototyping and manufacturing customized products.

Advantages of 3D Printing

- Rapid prototyping and reduced development time

- Customization of products

- Reduced material waste

- Ability to create complex geometries

For more information, visit the Wikipedia page on 3D printing.